Aerial Fiber Optic Cables Tutorial

Aerial fiber optic cables are used very commonly in optical communication nowadays. We can even see the aerial cables hanging in the pole around our daily life. In order to adjust to the harsh outdoor environment and prevent fiber theft, the aerial fiber optic cable is made up of different materials, which is not the same as a typical fiber optic cable. Today, we will take you to learn more about the aerial fiber optic cables.

What Is Aerial Fiber Optic Cable?

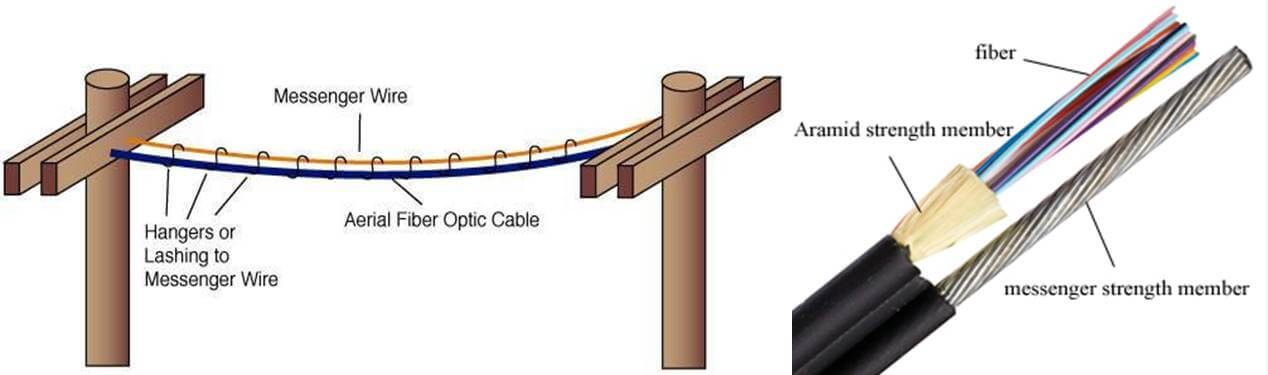

Aerial fiber optic cable is a type of fiber optic cables that is usually used for outside installation on poles. Due to its installation environment, the design of aerial fiber optic cable must consider to protect it from the destruction of the nature and man-made damage or theft. Aerial cable's laying method is not hard to implement as it can utilize the existing overhead pole line to install that saves more in construction costs and shortens the construction period. Aerial cables are mainly used for secondary trunk level and below and usually applied to flat terrain or low fluctuation area. They are easily affected by the natural disasters, such as typhoons, ice, floods etc. as well as the influence of an outside force and the mechanical strength weakening in themselves. Therefore, the failure rate of aerial fiber optic cables are higher than the pipeline or directly buried fiber optic cables.

Figure 1: Aerial fiber cable.

Figure 1: Aerial fiber cable.

Types of Aerial Fiber Optic Cables

According to the installation methods, aerial fiber optic cables can be generally classified as two types: catenary wire and self-supporting. Catenary Wire Aerial Cable is regular outdoor loose tube cables that can be helically lashed to a messenger or another cable (common in CATV). Self-Supporting Aerial Cable, or All-Dielectric Self-Supporting (ADSS) cable (the common style such as Figure-8 Aerial Cables), has cable bonded to an insulated steel or all-dielectric messenger for support. ADSS Cables are usually made of heavier jackets and stronger metal or aramid strength members. Nowadays, the self-supporting aerial fiber optic cables are more widely used by people.

As a familiar self-supporting aerial cables, figure-8 self-supporting aerial cables are designed for easy and economical one-step installation and widely used in long-haul and building network communication. According to the structures and materials of the cables, there are several kinds of figure-8 self-supporting aerial fiber cbales in the market, such as GYTC8S, GYXTC8Y, GYXTC8S etc. We can see the differences between GYTC8S, GYXTC8Y and GYXTC8S through the detailed information below.

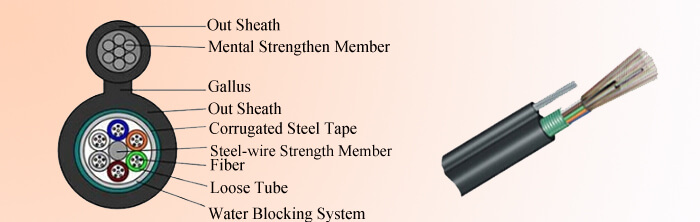

GYTC8S: GYTC8S is a typical self-supporting outdoor fiber optic cable. It's suitable for aerial applications while its nice moisture resistance performance and crush resistance performance are suitable for duct and buried method. The mental strength member is made up of stranded wires as the supporting part that are completed with a polyethylene sheath to be figure 8 structure. Corrugated steel tape armored and polyethylene outer sheath provide the crush resistance and gun shot resistance features. As the central strength, the steel-wire strength member improves the tensile strength. In addition, it is surrounded by the loose tube and water blocking system.

Figure 2: GYTC8S self-supporting outdoor fiber optic cable inner structure.

Figure 2: GYTC8S self-supporting outdoor fiber optic cable inner structure.

Features:

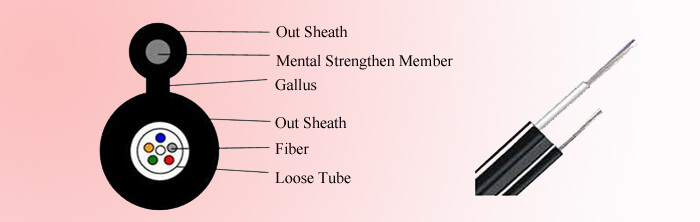

GYXTC8Y: GYXTC8Y is a light self-supporting cable with the figure-8 shape in the cross section that is suitable for installation in aerial environment for long haul communications. High tensile strength of stranded wires meet the requirement of self-supporting. It can also be used for duct and buried method. The mental strength member is similar to the GYTC8S. Steel wires and loose tubes filled with waterproof compound to ensure compact and longitudinally water blocking.

Figure 3: GYXTC8Y light self-supporting cable with the figure-8 shape.

Figure 3: GYXTC8Y light self-supporting cable with the figure-8 shape.

Features:

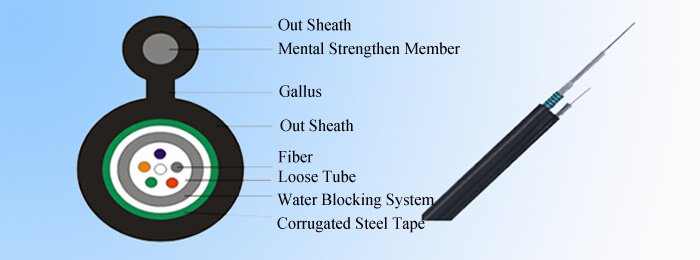

GYXTC8S: GYXTC8S is also suitable for installation in aerial environment for long-haul communications. This kind of figure-8 aerial cables is usually for 4-core to 12-core types. The water resistant tape provides water tight property. Corrugated steel tape and the polyethylene outer sheath provide crush resistance and gun shot resistance. The figure-8 steel wire works as self-supporting member providing excellent strain performance and convenient installation.

Figure 4: GYXTC8S fiber optic cable inner structure.

Figure 4: GYXTC8S fiber optic cable inner structure.

Features:

Tips for Aerial Fiber Optic Cables' Installation

When implementing the aerial fiber optic cables' installation, there are always two ways: lashing a fiber optic cable to a steel messenger or direct installation of self-supporting figure-8 aerial cables. There are some tips for better aerial installation.

1. Make clear what Problems we might meet during the installation. The following three points are the mostly common problems:

2. A perfect Planning solution is necessary before any aerial cable installations:

3. Safety during installation:

Summary

We mention aerial fiber optic cables and something about the aerial installation above. However, after learning this tutorial, it often comes down a question. When considering aerial fiber optic deployment, which types of aerial cable solution is most cost effective for you. ADSS cable is more expensive than loose tube cable (using in catenary wire installation), but labor and material costs can be lower for ADSS. And while ADSS hardware on a cost-per-pole basis is higher, this is often offset by the elimination of strand or lashing wire. In a word, explore your options based on your situation and then decide what makes the most sense for you. For example, in areas where a strand is already in place, catenary wire aerial fiber optic cables could be more cost-effective, while the opposite might be true in an area without a strand in place.